Crack- and Functional Tests on Sonotrodes and their Repair

Sonotrodes are expensive special tools. Therefore, each sonotrode construction should be designed in such a way as to guarantee an as long as possible service life. In case that the sonotrode does no longer work properly, it would be sensible to look for the reason.

For example, sonotrodes may crack due to a variety of reasons. (For further information, read our eBook „Lousy Waves“).

Crack Tests on Sonotrodes

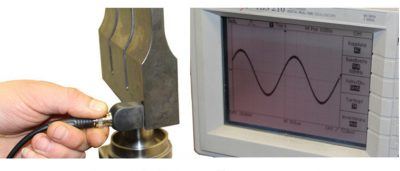

When assessing a sonotrode, the first thing to do is to test its basic functions and to sort out if the amplitude follows an even curve progression and if the frequency lies within a range which still can be “caught“ by the generator. The USM 3.1 together with an oscilloscope enables a quick test, even when in progress or during the production.

Measuring the sound waves and the frequency with the USM 3.1

Should there be a clear indication that the sonotrode has a crack, there will be no further need of continuing since cracks on sonotrodes cannot be repaired.

It is very easy to determine cracks: The sonotrode “screeches“ loudly. This is due to the fact that the sound wave movements – which are not, or hardly, heard when working with an accurate sonotrode- lead to side frequencies within the crack and which fall within an audible range. On the other hand, the sonotrode´s impedance rises considerably. In most cases a cracked sonotrode cannot even be set into oscillations.

It is always sensible to detect the progress of the crack, since, it may show a faulty construction or a faulty use.

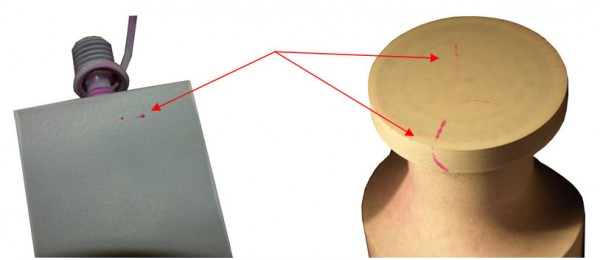

A common method for finding crack evidence is the so called Penetrant Testing. This method is not only non-destructive, but also easy to use, safe and very reliable.

With the so called Penetrant Testing (PT), two different means are applied. The cracks are easily detected thanks to an intense red colouring

There may be various reasons for the appearance of cracks. In most cases it is due to faulty constructions, operating errors, imprecise manufacturing or material fatigue.

Cavity

However, another reason for a cracking might be that a material with cavity inclusions has been used. Such a material is completely unsuitable for the construction of sonotrodes.

Cavity zone in a cut-open sonotrode. When under sound waves, cavities lead to voltage peaks and a total loss of the sonotrode

Rework on Sonotrodes

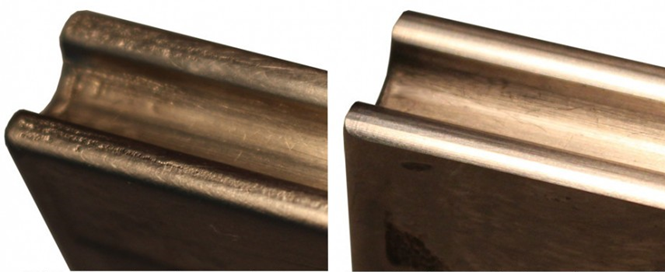

Nevertheless, sonotrodes are also subject to mechanical abrasion (especially when working with the so called metal-metal contact, to be found in film or tissue processing) and which after some time may make them unsuitable for extra sensitive or accurate applications. The possibility of reconditioning should already be envisaged when designing them. It is quite possible to construct the sonotrodes for many applications and enable their working surface so that it can be ground several times.

Sonotrode with abrasion and pitting (left). Sonotrode after post-processing – cost around 20% of the original price (right).