Well-functioning sonotrodes are of paramount importance for the entire ultrasound-welding process. Sonotrodes must oscillate at correct frequency, the waveform itself must be right, as well as the amplitude and the amplitude distribution.

Well-functioning sonotrodes are of paramount importance for the entire ultrasound-welding process. Sonotrodes must oscillate at correct frequency, the waveform itself must be right, as well as the amplitude and the amplitude distribution.

In addition, they must be geometrically precisely manufactured, the material used must be suitable for the application, the idle power should be as low as possible.

Only if all these requirements are met – in addition to some others – a sonotrode is properly designed and constructed.

This is not always the case.

Often, sonotrodes are either designed or built incorrectly or inexpertly reworked. As a consequence the welding performance is reduced and the entire process is uncertain, resulting in a considerable effort for the failure analysis required then.

That is why we pay particular attention to the optimization of existing sonotrodes.

Based on our extensive analysis and calculation capabilities, we are able to assess sonotrodes regarding their swinging quality and to implement improvements quickly and inexpensively.

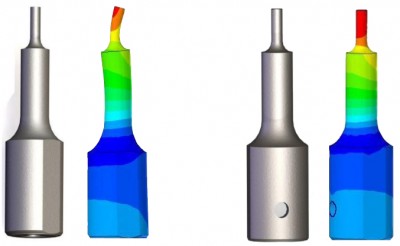

The sonotrode shown in the picture above is a typical example of improper oscillation behavior. Although it has certainly worked in the right frequency, the “wrinkling stress” at the top has led to extremely fast cracking. There were significant failure rates, often cracks occurred after very few welds already. This resulted in an immediate fracture of the sonotrode, which had to be scrapped and replaced.

Already small changes to the geometry resulted in a significant extension of the lifespan and an improvement in the welding results.

By the way: At the construction of sonotrodes we perform an FEM analysis in principle.

Open PDF Brochure Get a quote