It all started on our kitchen table. After work and the evening sandwiches it was cleared, then refilled with files and hammers, precision manufacturing equipment, freehand sketches, resistors, oils and fats. Coils were still wound manually with copper wires with a thickness as low as 0.1 mm – to save about 10 cents…A classical moonlighting activity. The day job as workshop manager at the Institute for Applied Physics of the University of Münster was “the profession”.

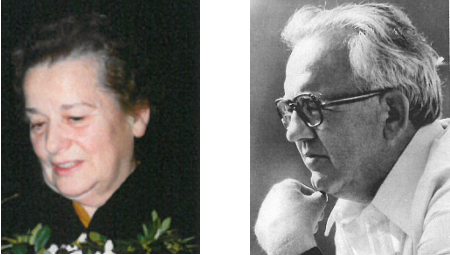

Ruth and Bernward Rittmeyer

A friend persuaded our father and grandfather Bernward Rittmeyer and his wife Ruth to strive for, originally joint, self-employment. On 05/01/1966 (indeed on May1st!) it was – with the approval of the university and, for reasons of financial security, at first alongside the existing employment relationship – finally time for the birth of the new small company FEINTECHNIK R.Rittmeyer & Co. The manufacturing site: in Münster, “An the Kleimannbrücke 10”; the size: not even 40 sqm; employees: one; equipment: 2 ancient, very simple turning machines (at least, no longer with belt drives…). A garage with a toilet – more was not possible initially. And since our father was still employed in “public service”, the wives became the founders.

This is how it all started.

Münster, Alfred-Krupp-Weg 76

Just a few months later, on 10/01/1966, it was however possible to expand the company’s floor space to luxurious 150 sqm. A rental floor at the Alfred Krupp-Weg 76, with the charm of post-war industrial architecture. Something that is unmatched today…

This was the floor in which the young company should develop. It was its home until the 3rdNovember 1978. The only advantages: affordable rent and in walking disance to the apartment. As provisional as this may seem nowadays – in these years the FEINTECHNIK progressed enormously:

- Self-employment of the founder

- From contract manufacturer to assembly company

- Training of first apprentices

- Internationalisation

- Development and construction of first cable stripping knife, later on

- Cable processing machines

- Participation of wife Ruth Rittmeyer

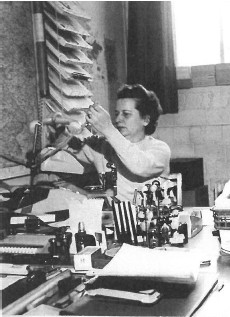

Ruth Rittmeyer 1967

- Participation of daughter Renate Rittmeyer-Müller

Renate Rittmeyer-Müller Hannover 1968

- Acquisition of an agency of the MEGOMAT AG from Switzerland

- Growth to approximately 10 employees

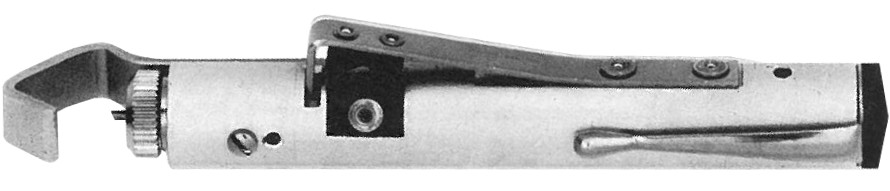

Does the name of the cable stripping knife, “JOKARI”, a small hand tool for electricians for the stripping of cables and wires, “ring a bell”? The “RI” still stands for “RITTMEYER” today. That was the kick-off for the entry into cable stripping technology.

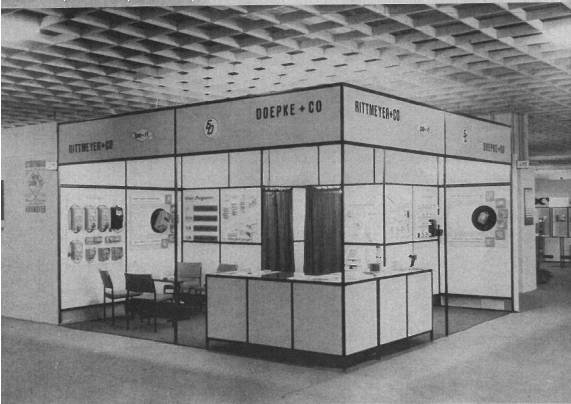

Hannover Fair 1968

Already at the Hanover trad fair 1968, the young company presented itself to the public, initially with its own small stripping knife F14. It became a hit, sold thousands of times worldwide, and contributed – along with other handheld stripping tools, which were consequently developed by B.Rittmeyer – decisively to the successful development of the company in the early years.

Cable stripping knife F 14

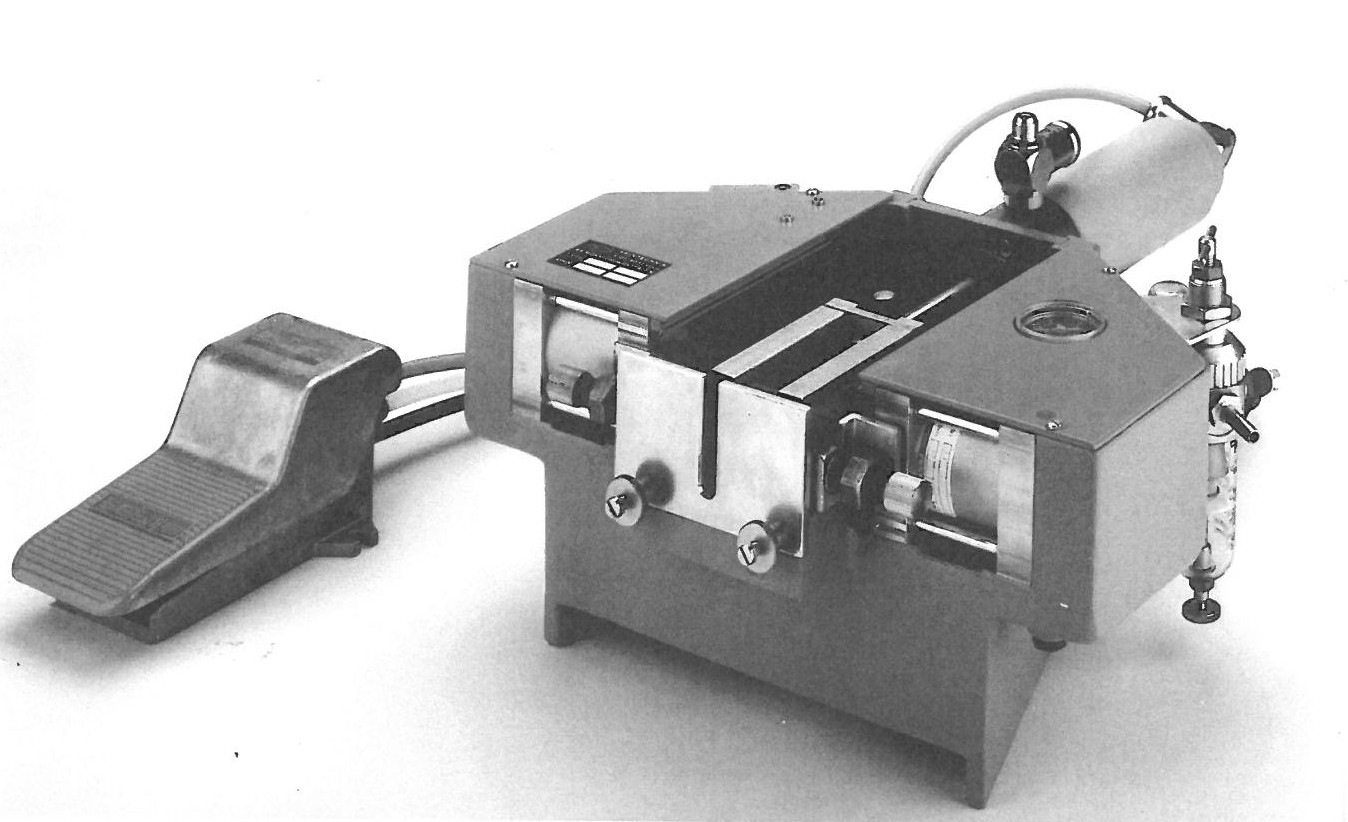

The first stripping machine was built in the late 60s – the AM1: conceived, developed and drawn in front of the black and white television set, between the news and test image.

AM 1

Moreover, a machine, which we, the successors, still manufacture. Certainly somewhat enhanced over time, but in principle the same design as in the beginning. Indestructible and strongly ignorant towards considerations such as follow-up business through spare parts requirements, limited lifetime, planned obsolescence.

Then, in November 1978, the next step: the proud move into an own hall at the Höltenweg 103 in Münster. Where we are still located…

FEINTECHNIK R.Rittmeyer GmbH in Münster today

Of course, the machine developments kept going. In the late 70s, the AV-0 came to the market, the world’s first machine with rotating knives that are positioned by an axially movable cone. In a slightly modified form, this principle was later used with our consent by the company Schleuniger AG for their first coaxial stripping machine.

Rotational stripping machine AV – 0

In the year 1986, the son Walter Rittmeyer also entered into the company. Unfortunately there was only a very short period of cooperation with his father – Bernward Rittmeyer died on 03/06/1987, a few days before his 65th birthday.

“Meanwhile”, special developments for various customers and institutions were always created over the years: e.g. a lottery wheel for what is today “WestLotto”, which was used in the third television program as a forerunner of the later Wednesday lottery draw. (What a huge excitement every time, hoping that this spacey monster really works and does not stop suddenly in front of an audience of millions in the middle of the draw…).

Lottery wheel for the WDR (Television broadcaster in Germany)

In the 90s we have built a dummy for a device that was conceived to measure variations in the ozone layer from space. The project was led by science astronaut Reinhard Furrer, who unfortunately also passed away too early at an air show in Berlin. The task had been to use space-qualified materials with specific alloys and to comply with typical atmospheric conditions in the space station MIR.

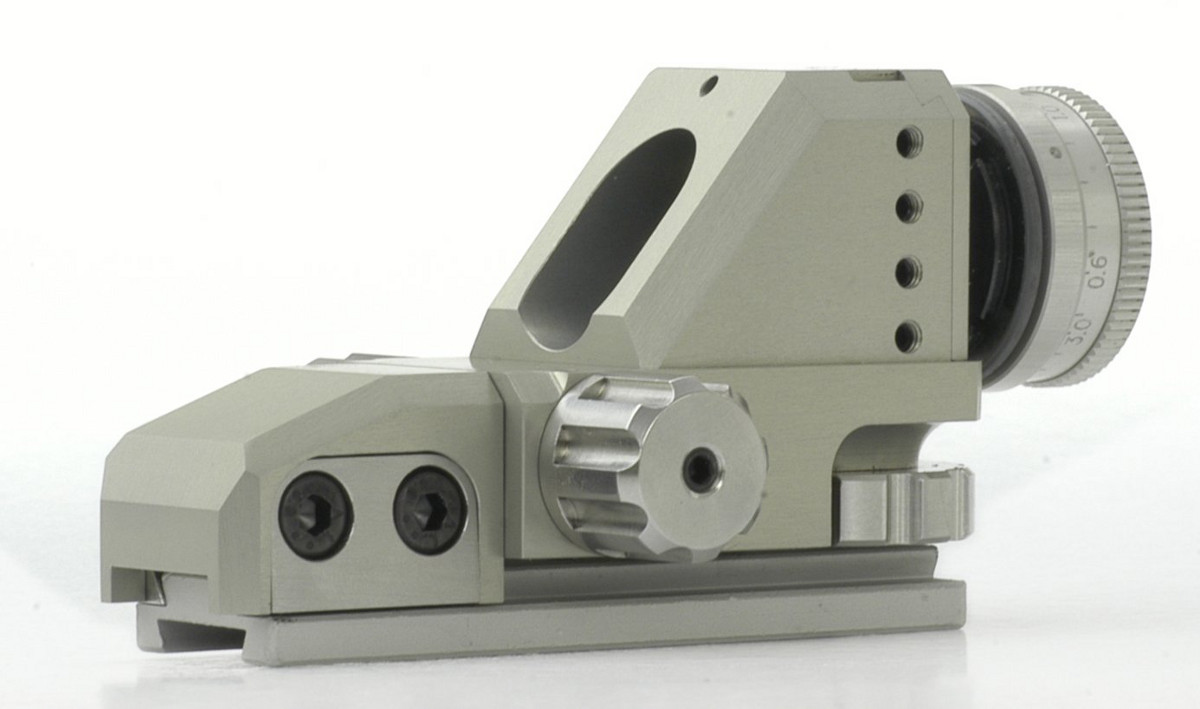

Or later in 2008, when “we became Olympic champion” at the Summer Games in Beijing… With a dioptre, developed by our employee Heiko Bröker. The Indian target shooter Abhinav Bindra had received one prototype for testing shortly before the Olympic Games and decided to use these, despite the very short settling time. And he did indeed win the first gold medal for India at the Olympics with this diopter.

Diopter “Free-Sight”

50 years FEINTECHNIK R.Rittmeyer GmbH – “the shop” is still going. For a long time and by now for several decades the company is managed by the siblings Renate Rittmeyer-Müller and Walter Rittmeyer, assisted since more than six years by the grandson M.Sc. Hannes Rittmeyer. And the work on the 4th generation has now started (even if the great-grandchildren are not yet aware of it now, forgivable given their age of 5 years and 5 weeks, respectively…).

The FEINTECHNIK R.Rittmeyer GmbH with 30 employees asserts itself in the fields cable processing machines, special machine manufacturing and development (primarily for medical technology) sonotrode manufacturing and – in the most determined manner since the beginning – classical precision engineering. This is our origin, we want to continue to maintain this job profile, also in memory of our father and grandfather, who was a passionate precision engineer.

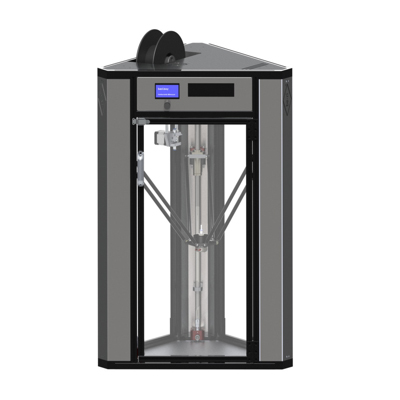

The tinkering gene was obviously passed on to us. As a result, we have most recently developed the “beri-boy“, a 3D-printer using FDM/FFF technology with mechanical engineering demands on precision and suitability for industrial applications. The aim is to provide a “helpful comrade” for developers, designers, creatives and professional amateurs. The launch is scheduled as of April 2017.

3D – Deltaprinter beri-boy

50 years as mechanical engineers – a time that covers all at the ups and downs, successes and catastrophic failures. We are “olympic champions” but just as well “got off with a slap on the wrist”. For our international success as a small, innovative mechanical engineering company, we also have to thank our employees. Many accompany and support us for decades and have begun already as apprentices with us. They have been an instrumental part of our existence and without their reliable contribution and solidarity we would not have survived during the harsh years.

We also want to thank our bank, the Volksbank (although it also has a more complicated name by now, it will always be “die Volksbank” for us). Without their thoughtful and reliable support the coping with many crises in the past would, in the proverbial sense, “gone pear-shaped”. And finally – Thanks a lot, of course, to our many thousands of customers, scattered around the world on all continents. Without them, we are nothing – and we are aware of this.

Where are we heading? Maybe just business as usual, with continuity and the lustful willingness for constant change?

With thanks and best regards to all our well-wishers:

Renate Rittmeyer-Müller——————–Walter Rittmeyer——————–Hannes Rittmeyer